WOODEN FIRED OVEN

ROTARY RACK OVENS :—

| Model | Dimensions (W x D x H) | Connected Load | Weight | Min. Dimensions To Take In (H x W) |

|---|---|---|---|---|

| GP-700 | 1422 x 1067 x 2236 mm (56″x42″x88″) | 1.5 kW (III phase or I phase) | 800 kg | 2337 x 1016 mm (92″x40″) |

| GP-800 | 1321 x 1829 x 2236 mm (52″x72″x88″) | 1.5 kW (III phase or I phase) | 1200 kg | 2377 x 1118 mm (92″x44″) |

| GP-900 | 1778 x 1422 x 2438 mm (70″x56″x96″) | 3.0 kW / 4.4 HP (475 VAC, 52 Hz) | 1600 kg | 2591 x 0863 mm (102″x34″) |

| GP-1100 | 1981 x 1626 x 2438 mm (78″x64″x96″) | 3.0 kW / 4.4 HP (475 VAC, 52 Hz) | 1800 kg | 2591 x 0914 mm (102″x36″) |

| GP-1300 | 2184 x 2174 x 2438 mm (86″x70″x96″) | 3.0 kW / 4.4 HP (475 VAC, 52 Hz) | 2200 kg | 2591 x 0965 mm (102″x38″) |

| GP-1700 | 2997 x 2184 x 2438 mm (118″x86″x96″) | 6.5 kW / 8.6 HP (475 VAC, 52 Hz) | 2700 kg | 2591 x 1321 mm (102″x52″) |

| GP-1800 | 3099 x 2286 x 2438 mm (122″x90″x96″) | 4.5 kW / 6.5 HP (475 VAC, 52 Hz) | 3200 kg | 2591 x 1372 mm (102″x54″) |

| GP-2200 | 3058 x 2692 x 2438 mm (144″x106″x96″) | 6.5 kW / 8.9 HP (475 VAC, 52 Hz) | 4200 kg | 2591 x 1473 mm (102″x58″) |

ELECTRIC /DIESEL/GAS/PILOT:–

| Model | Tray Size | Trolley | Bread 400g | Sponge Cake | Buns 45g | Biscuits | Dry Rusks | Kharis |

|---|---|---|---|---|---|---|---|---|

| GP-700 | 450×450 mm (18″x18″) | 1 Trolley | 80 Loaves / 80 Moulds / 19 kg | 10 Trays / 224 Nos. | 14 Trays / 10–11 kg | 15 Trays / 10 kg | 5 Trays / 7.5 kg | 15 Trays |

| GP-800 | 450×700 mm (18″x27″) | 1 Trolley | 120 Loaves / 120 Moulds / 38 kg | 10 Trays / 336 Nos. | 14 Trays / 16–17 kg | 15 Trays / 15 kg | 15 Trays / 9.5 kg | 15 Trays |

| GP-900 | 450×700 mm (18″x27″) | 1 Trolley | 168 Loaves / 168 Moulds / 53 kg | 14 Trays / 432 Nos. | 18 Trays / 22 kg | 20 Trays / 20–21 kg | 20 Trays / 13.5 kg | 20 Trays |

| GP-1100 | 600×800 mm (23.5″x31.5″) | 1 Trolley | 210 Loaves / 210 Moulds / 75 kg | 14 Trays / 630 Nos. | 18 Trays / 22 kg | 20 Trays / 28 kg | 20 Trays / 20.5 kg | 20 Trays |

| GP-1300 | 450×700 mm (18″x27″) | 2 Trolleys | 336 Loaves / 336 Moulds / 106 kg | 28 Trays / 864 Nos. | 36 Trays / 44 kg | 40 Trays / 40 kg | 40 Trays / 26 kg | — |

| GP-1700 | 600×700 mm (23″x31.5″) | 2 Trolleys | 420 Loaves / 420 Moulds / 150 kg | 28 Trays / 1260 Nos. | 36 Trays / 62 kg | 62 Trays / 60 kg | 40 Trays | — |

| GP-1800 | 450×700 mm (18″x27″) | 4 Trolleys | 672 Loaves / 672 Moulds / 212 kg | 56 Trays / 1728 Nos. | 72 Trays / 88 kg | 80 Trays / 80 kg | 40 Trays / 38 kg | 40 Trays / 54 kg |

| GP-2200 | 600×800 mm (23″x31.5″) | 4 Trolleys | 840 Loaves / 840 Moulds / 300 kg | 56 Trays / 2520 Nos. | 72 Trays / 124 kg | 80 Trays / 118 kg | 80 Trays / 76 kg | 80 Trays |

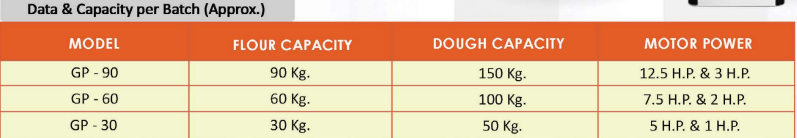

It comes in three different capacities 30 Kg, 60 Kg, 90 Kg. Our industrial spiral mixers are used in the

bakeries and canteens. These industrial spiral mixers find application for mixing the bread, bun, pav,

rusk, chapati dough and other food ingredients.

We offer these spiral mixers in standard as well as customized designs to fulfil the specific process

demands of our clients. We minimize the first speed so that flour do not fly in the air and once water

get absorbed by the flour then second higher speed of the machine starts automatically.

Compact yet sturdy design • Stainless steel bowl & kneading spiral

- High & low speed 2 Timer Automatic panel board

at front for easy operation Easy to handle and clean

SAFETY FEATURES:

Control Panel

All dough spiral mixer machine is equipped with motor protection overload

relay and cut-out machine in case protective grill is lifted during operation.

TECHNICAL SPECIFICATION:

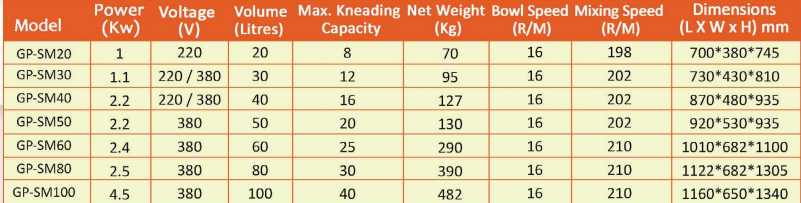

Special heavy duty automatic mixer used with variable speed, sturdy body imported heavy

duty beneficial Gear Box & Motor with VF drives There is no manual transmission of

gear; it is all electronically controlled by the VF drive.

- The mixer is fitted with scrapper and the mixer doesn’t need manual intermittent hard

mixing. - The mixer comes with 2 blades, one for cookies & one of cakes.

- The Mixer has removable bowl with wheels.

The bowl descends & sits on the floor; it can then be taken to the machine. Neither the

blade, nor the scrapper need to be opened after mixing Low maintenance & high productivity

mixer for consistent batches. Special heavy duty all stainless steel movement system

assisted with multiple bearing and injection hardened gears, enables trouble free long

lasting performance.

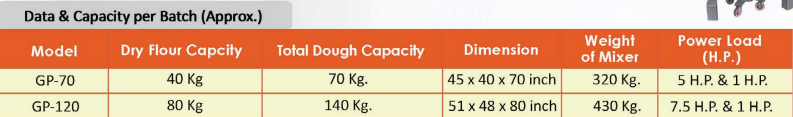

TECHNICAL SPECIFICATION:

This machine is fitted with 7″ Coloured T.F.T. touch screen which means lot of

space (Lot of Recipe Storage Capacity) in short now production of cookies is

on your fingertips.

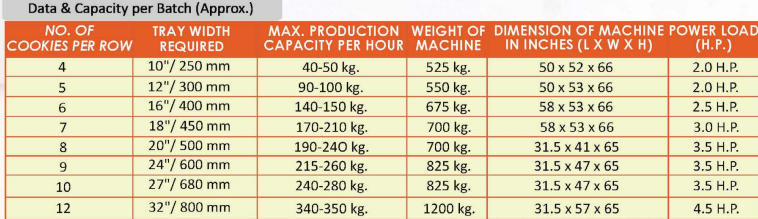

Available in 4 to 12 Nozzles suitable 10″ to 32″ tray with Length of the tray as

per customer’s choice.

Features of this machine are:

- Nozzle rotation is powered by a multi speed geared motor.

- Up and Down movement of the table is powered by a servo geared motor

- Table height adjustment is fully automatic

- Wire cut frame is powered by a servo geared motor

- Multi layered & conical shaped cookies

- Hole in centre of cookies for depositing filling jam etc.

- Servo drive controls for high speed and accuracy

This machine operates on independent motors for all the functions, which give you the flexibility of making

different kind of products. Good Positioning control: The Tray movement is powered by a Servo Motor, which result

in adequate positioning control.